Technical Parameter

| Parameter |

Part A |

Part B |

| Color |

white

|

Yellow |

| Viscosity(cps)25℃ |

10000-20000 |

10000-20000 |

| Curing Ccomponent |

100% |

| Curing speed |

Initial curing:8-12minutes Totally curing:24hour

|

| Guarantee period(25°C) |

12months

|

| Tensile shear strength(Mpa) |

≥25

|

| Impact strength(kj/m²) |

≥20

|

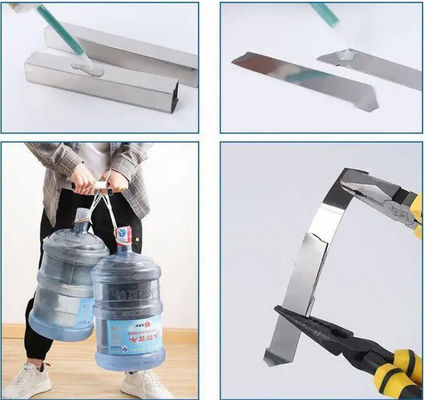

FEATURES

DY-J8856 high-performance structural adhesive is a brother developed a high-performance modified acrylic structural adhesive, at room temperature (25 ℃) can quickly solidification, high thixotropy, no flow of raw with a strong bonding Strength, good weather resistance. Good toughness after curing film. Impact and Mao cut force particularly strong. High temperature performance. Electrical insulation performance.

Application

starting dynamo,magneto,fan electromotor, heater motor,ferrite, motor casing,metal,plastic,glass,rubber.

| Stone |

laptop Components |

Phone Back Cover Battery |

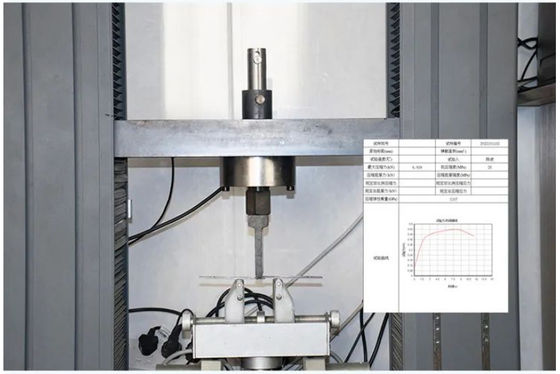

Strength Testing

Two iron sheets were bonded and fixed with DY-J8856, and their bonding strength was tested by placing them on a tensile force tester. The greater the tensile force, the greater the bonding strength, with a maximum force of 6.939 kn

Pressure Testing

This product is developed using advanced technology and technology. At room temperature, it has quckly curing and good flexibility with strong impact resistance and shear strength MPa25

Packing

50ml/tube;10tubes/small box;60tubes/big box

400ml/tube;6tubes/small box;24tubes/big box

2kg/pair;6pairs/big box

5kg/pair;3pairs/big box

15kg/barrel;30kg/pair

OPEATION METHODS

1.Keep the surface dry and clean,needn’t strictly degreasing

2.Installing the mixing nozzle.

3.Evenly mix the A and B component with 1:1 ratio.

4.10 minutes for initial curing, 15 minutes for initial curing and pressing, and 24 hours for optimal adhesion

NOTICE:

1. This adhesive has a pungent odor. It is recommended to operate in a ventilated environment and let it air for 1 day without any odor 2. After bonding and binding with adhesive, do not move the adhesive. Let it stand for 24 hours to reach its strength. If the adhesive is applied too much, let it stand for 48 hours

3. This adhesive, A: transparent, B: light yellow, and should be used up within 5 minutes after extrusion and mixing. After drying, it will turn milky white

4. A and B mixed in large quantities can quickly solidify and cause danger, special care should be taken

5. After mixing all of this product, there will be a chemical reaction, which will generate heat and smoke, and may have a corrosive effect on some products. It is recommended to use this product appropriately for valuable goods

6. This product has very strong adhesion and performs better than instant drying adhesive, especially for metal bonding

7. This product must be uniformly mixed with AB before it can react. Uneven mixing may cause non drying and solidification

8. After use, if the skin adheres to this agent, it should be washed with soap

9. This adhesive is difficult to remove as long as it is firmly adhered. If it must be removed, please soak it in a glue remover for a while. It needs to be repeated many times. If the adhesive layer is thick, it may not be able to be removed.

Packaging & Shipping

| Packaging |

Shipping |

|

A:20g/card

24 cards/inner box

288 cards/ctn

DIM:47x46x35cm.

B: 80G/card

12 cards/inner box

144 cards/ctn

DIM:68X37X35CM

|

1.FOB Terms(FOB GUANGZHOU/SHANGHAI/CHANGSHA) or EX Works.

2.Free sample.

3. 24 hours after-sale service.

4.Customized design and brand is ok.

|

How to use:

1. Clean the surface, keep dry and get rid of the grease, rust. Otherwise, it would effect the solidifying speed a nd intensity. For metal material, remove the oil and rust firstly, then wash the surface with ethyl ester. For non metal, wash the surface with methyl chloroform.

2. Use the cap to cut through the nozzle. Pile out the small quantity glue liquid, drop the glue onto the surface (only lubricate the surface), press and bond the material hardly.

3. The best time to use: at temperature 20~25°C, relative humidity 50%.

Warning:

1. Take precaution against touching by the hands or eyes. If does, wash with dip in the water, do not peel the glue by force. If getting in the eyes, wash with water at once then see the doctor for further steps.

2. The glue has irritant odor. Keep the environment be ventilative and wear glasses to protect the eyes during long term usage.

3. Tighten the lid carefully after applying.

4. Please keep out of the touching by kid.

Storage:

1. The product is nonflammable. Keep dry and out of light, low temperature (20-25°C) during storage. The shelf life is one year.

2. If the glue does not solidifying beyond the shelf life, it could be used still. But the solidifying speed and adhesive intensity would be affected at some degree.

Scope Of Application:

This product could be applied to bond of metal, rubber, plastic, wood, pottery in the fields of daily household repairing, arts making and repairing, apparatus first orienting etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!